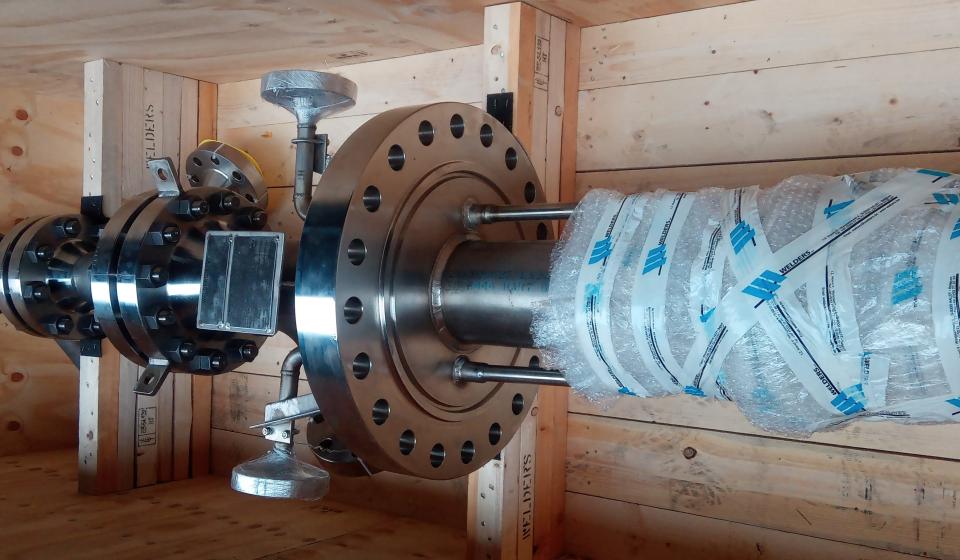

Custom built products

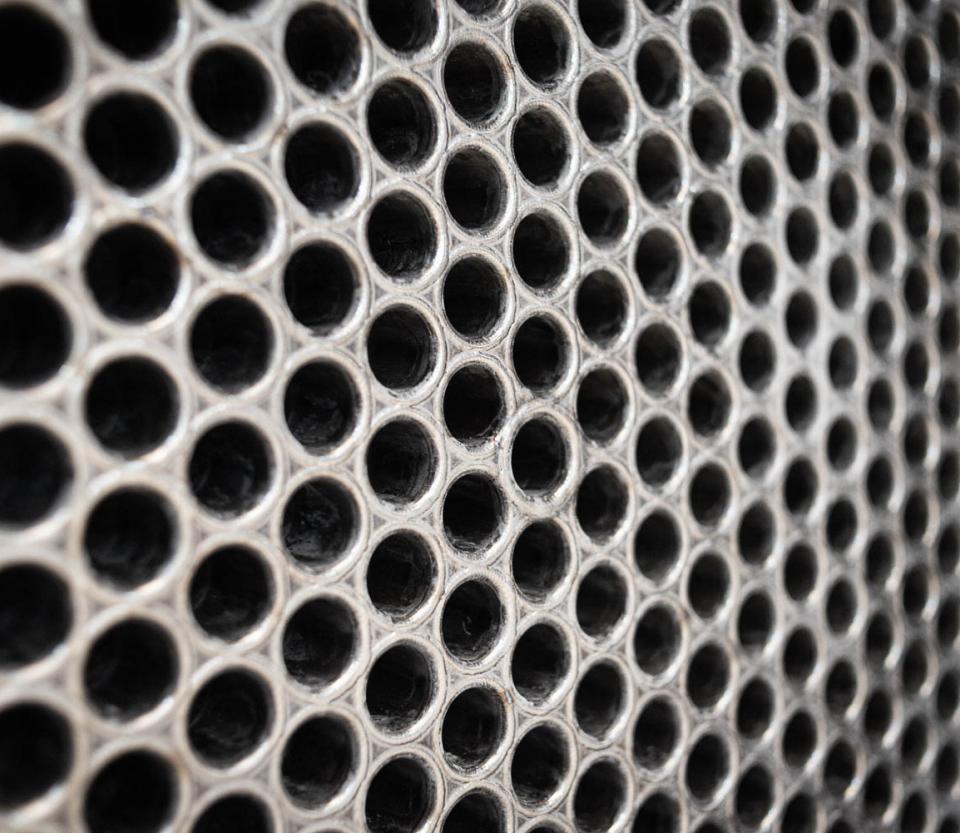

Over 7 decades, Welders N.V. has gained an extensive engineering expertise and fabrication know-how in high-integrity custom-built process equipment in heat- and corrosion resistant alloys used in numerous applications.

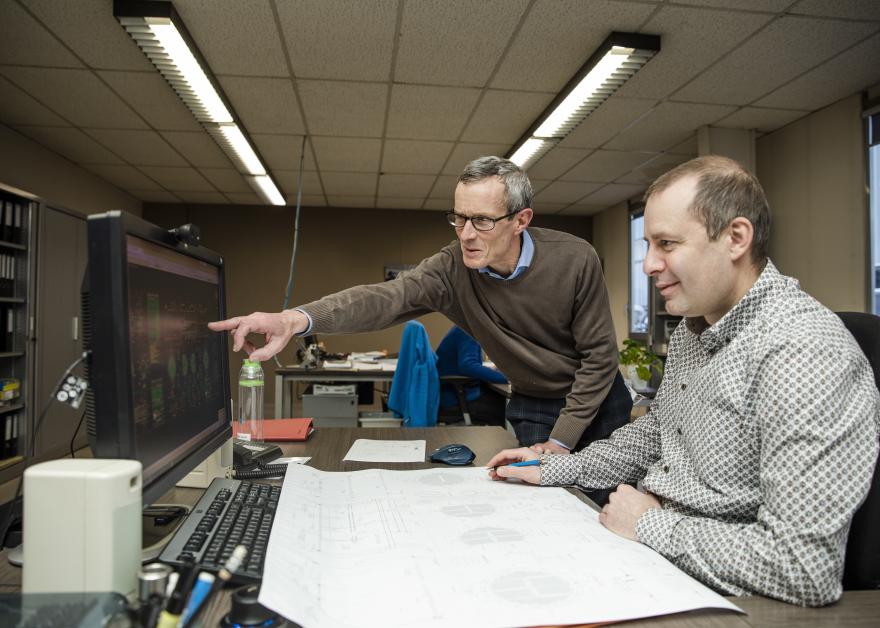

Welders’ Design and Engineering Department operates a comprehensive system, using software of international repute for thermal rating, stress analysis, wind load and seismic resistance calculations, as applicable. Combined with our expertise, it enables Welders’ engineers to optimise the equipment sizing and configuration and to maximize its cost-effectiveness.

Industries served

The equipment constructed by Welders N.V. is used in numerous applications, particularly in the hydrocarbon and downstream industries, but also in other industries featuring aggressive atmospheres or operating in environments calling for heat or corrosion resistant materials.

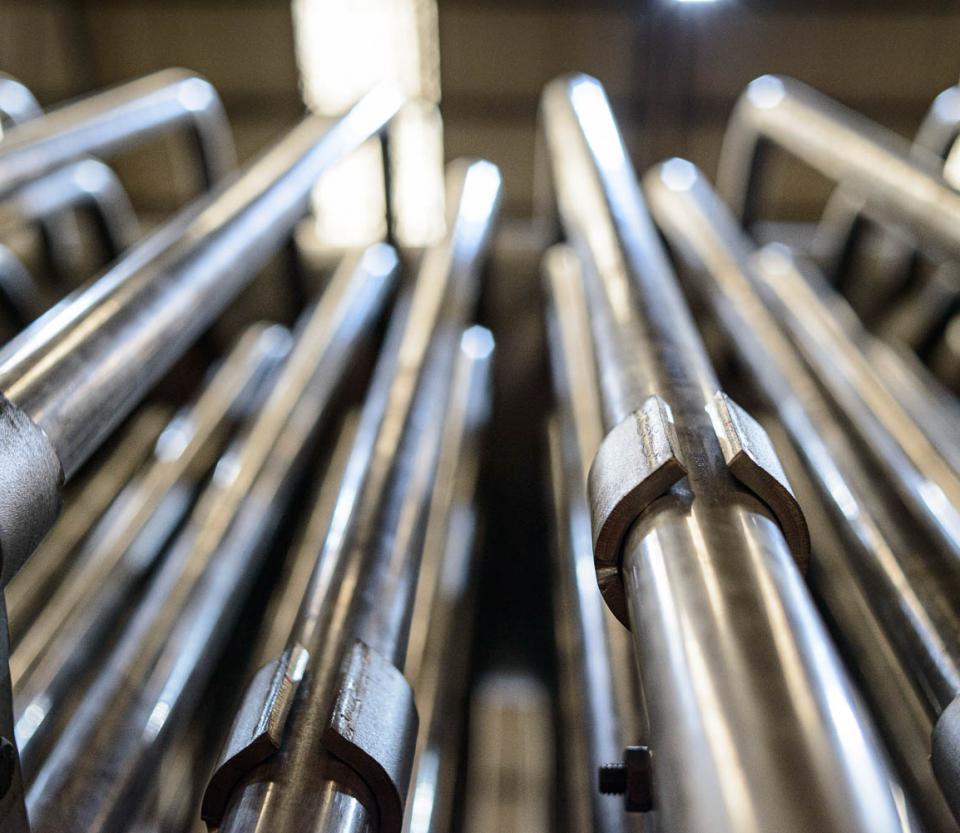

Welding techniques

For each project, the most suitable welding method is selected depending upon the type of base material(s), the heat input and as per the customer requirements.

Throughout the years Welders has built-up an extensive experience with the most common welding techniques, such as:

* Flux Cored Arc Welding

* Gas Metal Arc Welding

* Gas Tungsten Arc Welding

* Plasma Arc Welding

* Submerged Arc Welding

* Orbital Welding

Corresponding welding procedures are available and are continuously developed and updated.